Double Trolley Hook Overhead Crane Applications

Our Double Trolley Hook Overhead Crane lifts long, heavy materials safely in many industries.

1. Industrial Workshops & Factories

Moves steel pipes, bars, wood, and paper tubes in machine shops.

Helps in metal factories, assembly lines, and production areas.

2. Warehouses & Storage Yards

Carries long items like lumber, metal rods, and plastic tubes indoors and outdoors.

Saves space in logistics centers and storage yards.

3. Mining & Heavy Material Handling

Lifts ore, equipment, and construction materials in mines (safe zones only).

Works well in quarries and mineral plants.

4. Power Plants & Energy Sector

5. Transport & Loading Areas

Where It Cannot Be Used

⚠️ Not safe for:

Explosive or flammable areas (chemical plants, oil refineries).

Acidic or alkaline environments.

Extreme heat (foundries, smelting zones).

Why Choose This Crane?

✔ Balanced Lifting: Two trolleys handle long materials smoothly.

✔ Customizable: Fits factories, mines, and yards with adjustable options.

✔ Safe: Built-in protections for secure operation.

Where Double Trolley Bridge Cranes Are Used

Ports & Docks

Faster Container Handling: Two trolleys work together, speeding up ship loading by 50%+.

Heavy Cargo: Lifts large machines, steel, and other heavy items.

Manufacturing

Warehouses & Logistics

Storage & Sorting: Handles goods in and out fast.

Large Cargo Transport: Moves paper rolls, wood, and more in logistics hubs.

Construction

Building Materials: Lifts steel, wood, and prefab parts.

Heavy Equipment Setup: Installs cranes and elevators safely.

Energy Sector

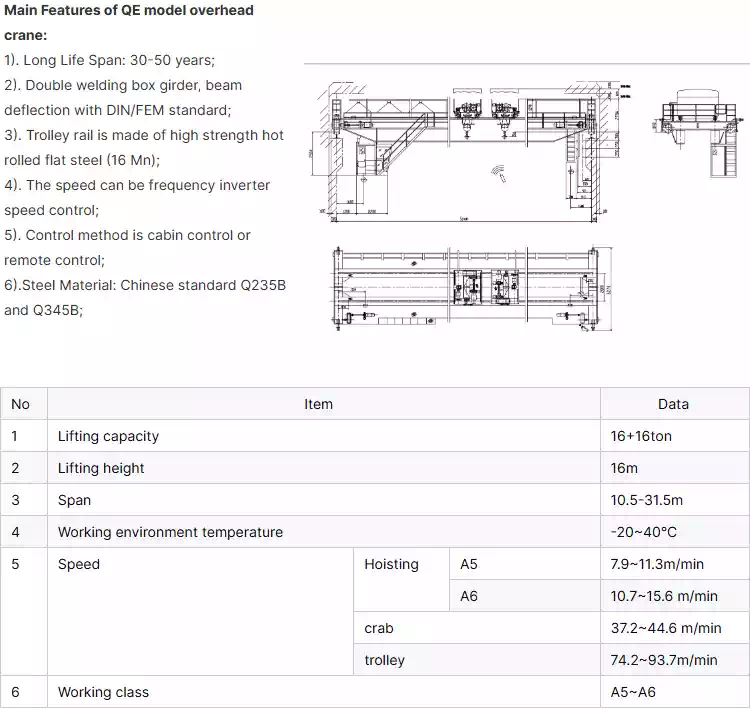

QE Double Trolley Bridge Crane Details

Key Features

Models & Specs

Model: QEhs

Capacity: 10t (5+5), 16t (8+8), 20t (10+10), 30t (15+15), 300t (150+150) – Custom sizes available.

Span: 7m-50m (custom).

Lift Height: 6m-30m (custom).

Duty Class: A4-A8 (based on usage).

How It Works

Cab Control: Easy to use with clear views. Options for fans, AC, and alarms.

Safe Access: Ladders for operators and repair crews.

Best For

Wind towers, pipes, logs, paper rolls, steel, and long materials.

Works in: -20°C to +40°C, humidity ≤85%, altitude ≤1000m. Add rain covers for outdoor use.

Note: This crane is semi-custom. We adjust rails and specs to fit your site.

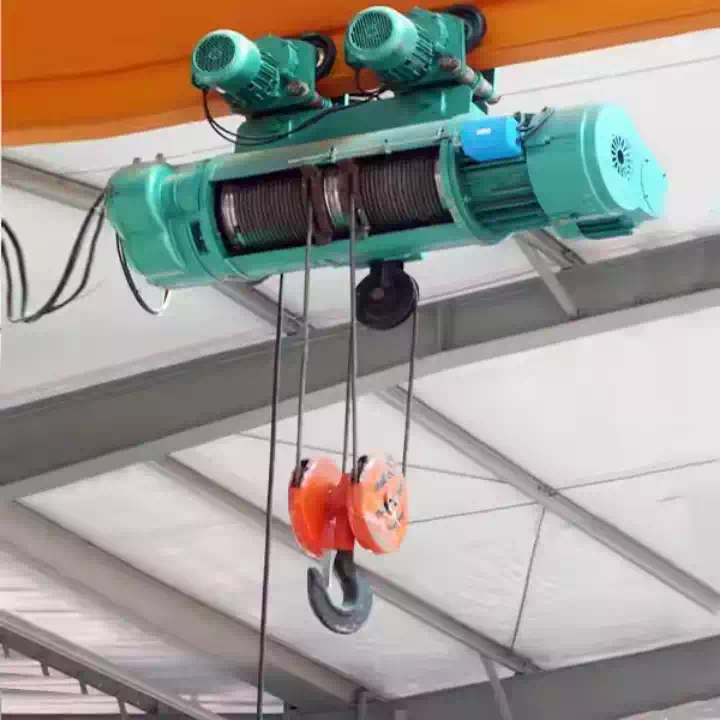

Lifting hook

Lifting hook

Grab bucket

Grab bucket

Magnetic chuck

Magnetic chuck